Discover the significance, components, and procedures of air brake checks, while learning about common issues and the benefits of regular inspections for safety.When it comes to vehicle safety, conducting a thorough air brake check is crucial, especially for heavy-duty trucks and commercial vehicles. Air brakes, designed to provide reliable stopping power, require regular inspection to ensure optimal performance and safety. Neglecting these checks can lead to serious mechanical failures and accidents on the road. This blog post will delve into the importance of air brake checks, outlining the key components to inspect and the step-by-step procedure to follow. We’ll also highlight common issues that can arise and the significant benefits of maintaining a routine air brake check schedule. By understanding and implementing these practices, drivers can enhance their safety while ensuring smooth operation on the roads. Let’s dive into the essentials of air brake maintenance!

Importance of Air Brake Check

The air brake system is a critical component of any vehicle that relies on air brakes, particularly commercial vehicles like trucks and buses. Regular air brake checks play a vital role in ensuring safety on the road. Below are the reasons why these checks are essential:

- Safety: The primary importance of an air brake check is to ensure the safety of the vehicle operator, passengers, and other road users. A malfunctioning brake system can lead to accidents.

- Performance: Regular checks help maintain the performance of the air brake system, ensuring that it responds quickly and effectively when needed.

- Compliance: Many regions have strict regulations regarding vehicle maintenance. Regular air brake checks help ensure compliance with these laws, preventing fines and legal issues.

- Cost Efficiency: Identifying and addressing issues early can save significant repair costs compared to delaying maintenance until a severe problem arises.

- Longevity: Proper maintenance and regular checks can extend the life of the air brake components, delaying the need for costly replacements.

Conducting air brake checks is not only a matter of regulatory compliance but also a fundamental aspect of responsible vehicle ownership and operation. Ensuring your air brake system is functioning optimally can make a significant difference in safety and efficiency.

Components to Inspect

When performing an air brake check, it’s essential to thoroughly inspect various components to ensure safety and reliability. Each component plays a crucial role in the overall functionality of the brake system. Here’s a breakdown of the vital components you should inspect:

| Component | Description | Inspection Tips |

|---|---|---|

| Brake Chambers | Houses the diaphragm that receives air pressure to apply the brake. | Check for cracks and ensure secure mounting. |

| Air Lines | Flexibly transport compressed air throughout the brake system. | Look for leaks, kinks, or wear and replace as necessary. |

| Slack Adjusters | Adjusts the brake shoes to maintain proper brake timing and effectiveness. | Ensure they are free of rust and operate properly. |

| Brake Shoes and Drums | Provide the actual friction for slowing down the vehicle. | Inspect for thickness and any signs of scoring or damage. |

| Parking Brake | Holds the vehicle in place when parked. | Test functionality and check the adjustment; ensure it holds securely. |

In addition to the components listed above, regular visual inspections can help identify potential issues before they result in significant problems. This proactive approach is essential in maintaining the integrity of your air brake system.

Remember that even minor inconsistencies in any of these components can lead to inefficiencies or failure. Carry out these inspections routinely as part of your air brake check procedure for optimal performance and safety.

Procedure for Air Brake Check

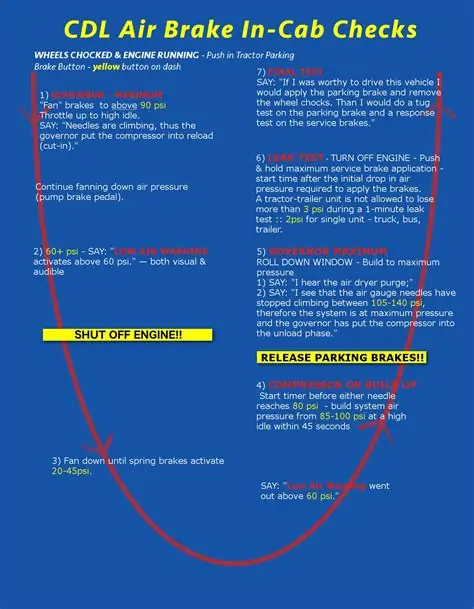

Conducting an air brake check is crucial for ensuring the safety and efficiency of commercial vehicles. Below is a step-by-step guide to performing a thorough air brake check:

- Preparation:

- Gather necessary tools such as a pressure gauge, wrenches, and a flashlight.

- Ensure the vehicle is parked on a level surface with the parking brake applied.

- Initial Inspection:

- Examine the air brake system components for any visible signs of wear or damage.

- Check for air leaks in the hoses and fittings.

- Verify that the air tanks are free from rust and moisture.

- Testing Low Air Pressure Warning:

- Start the engine and allow the air compressor to build pressure.

- Observe the low-air warning signal; it should activate at a pressure around 60 psi.

- Checking Air Pressure:

- Turn off the engine and monitor the air pressure; it should not drop significantly during the 1-minute observation period.

- If the pressure drop exceeds 3 psi for a straight truck or 4 psi for a combination vehicle, further investigation is needed.

- Application of Brakes:

- Apply the brakes and hold the pedal down.

- Check for any immediate pressure drop; this indicates potential issues with the brake system.

-

Common Issues Found

When conducting an air brake check, it’s essential to be aware of the common issues that can arise. These issues may lead to brake failure, unsafe driving conditions, and potentially disastrous outcomes. Here are some of the most commonly encountered problems:

Issue Description Recommended Action Air Leaks Leaks in the air system can lead to inadequate pressure for effective braking. Inspect hoses and fittings for wear and replace as necessary. Poorly Adjusted Brakes Improperly adjusted brakes can result in uneven braking power. Regularly check and adjust brake slack as needed. Contaminated Brake Fluid Contamination can lead to reduced brake performance and corrosion. Ensure fluid is clean, and replace it if necessary. Malfunctioning Components Various components such as the compressor, governor, or modulating valve can fail or perform poorly. Inspect and test all components regularly; replace faulty parts. Worn Brake Linings Brake linings that are too worn can significantly reduce stopping power. Check the thickness of the linings and replace them if they are below the recommended level. Addressing these common issues promptly can enhance safety and ensure the longevity of your air brake system. Regular checks and maintenance can vastly reduce the likelihood of these problems recurring.

Benefits of Regular Air Brake Checks

Conducting regular air brake checks is not merely a routine; it’s a critical component of vehicle maintenance, particularly for commercial and heavy-duty vehicles. Below are some of the key benefits of ensuring that these checks are performed consistently:

- Enhanced Safety: Regular air brake checks significantly reduce the risk of brake failure, enhancing the safety of the driver, passengers, and other road users.

- Improved Performance: Frequent inspections help in maintaining optimal performance levels of the air brakes, ensuring effective stopping power during operation.

- Cost Savings: Detecting and addressing issues during routine checks can prevent emergency repairs, saving money over time.

- Increased Vehicle Longevity: Regular maintenance, including air brake checks, contributes to the overall health of the vehicle, leading to a longer lifespan.

- Compliance with Regulations: Many jurisdictions require regular inspections of air brake systems to comply with safety regulations, helping to avoid penalties and fines.

- Minimized Downtime: Scheduled checks prevent unexpected breakdowns, minimizing vehicle downtime and ensuring steady operational efficiency.

In summary, the benefits of regular air brake checks extend beyond compliance; they are essential for safety, performance, and cost-effectiveness in heavy vehicle operations.

Frequently Asked Questions

What is an air brake system?

An air brake system is a type of braking system that uses compressed air to apply the brakes. It is commonly used in large vehicles like trucks and buses.

Why is an air brake check important?

An air brake check is crucial for safety. It ensures that the braking system is functioning properly, which is essential for preventing accidents and maintaining control of the vehicle.

What are the main components of an air brake system?

The main components of an air brake system include the air compressor, air tanks, brake chambers, and the brake pads or shoes.

How often should air brake checks be performed?

Air brake checks should typically be performed before each trip, as part of the pre-trip inspection, and regularly as part of routine maintenance.

What are some common issues found during an air brake check?

Common issues may include air leaks, worn brake pads, faulty brake chambers, or insufficient air pressure in the system.

What steps are involved in conducting an air brake check?

Steps typically include checking the air pressure, inspecting the brake components for wear, testing the brake functionality, and ensuring there are no leaks in the air system.

What should a driver do if they find a problem during an air brake check?

If a driver finds a problem during an air brake check, they should not drive the vehicle until the issue is resolved. It’s important to report the problem and have it repaired by a qualified technician.