Learn about air brake check valves: their function, importance of regular inspections, signs of faults, and effective maintenance practices for optimal performance.In the world of heavy-duty vehicles and pneumatic brake systems, the air brake check valve plays a crucial role in ensuring safety and reliability. This often-overlooked component regulates air flow, preventing backflow and maintaining optimal pressure within the braking system. Understanding how the check valve functions, as well as its significance, is critical for vehicle operators and maintenance personnel alike. As we delve into the importance of regular inspections, we’ll explore the telltale signs of a faulty check valve and how proactive maintenance practices can enhance overall performance. Whether you’re a seasoned professional or a newcomer to the industry, this comprehensive guide will equip you with the knowledge to keep your braking system in top shape.

What is an Air Brake Check Valve?

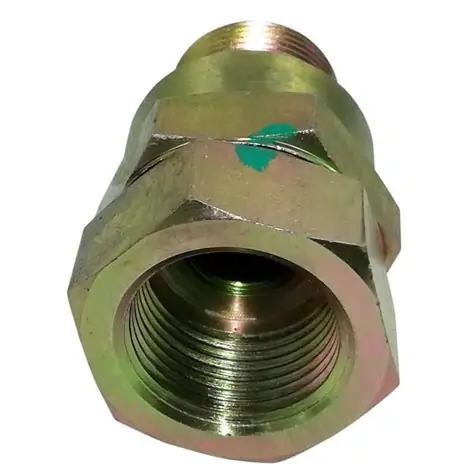

An air brake check valve is a crucial component in the air brake system of commercial and heavy-duty vehicles. Its primary role is to allow the flow of compressed air in one direction while preventing backflow, which could compromise the system’s efficiency and safety.

The check valve is typically installed between the air compressor and the air storage tanks to maintain consistent pressure and ensure that the air brake system functions correctly.

Key Features of an Air Brake Check Valve:

- One-Way Flow: The valve permits air to pass through in a single direction, ensuring proper brake function.

- Pressure Maintenance: It helps maintain the necessary pressure in the air storage system for effective brake operations.

- Failure Prevention: By preventing backflow, it avoids potential system failures and enhances overall vehicle safety.

In summary, the air brake check valve plays a vital role in maintaining the functionality and reliability of air brake systems, making it an essential component for vehicle safety.

Function of the Check Valve

The check valve plays a crucial role in the air brake system of vehicles, particularly in heavy-duty trucks and buses. Its primary function is to ensure that air flows in one direction and to prevent backflow that could compromise the system’s integrity.

Specifically, the check valve operates in the following ways:

- Maintaining Pressure: The check valve ensures that air pressure is retained within the brake lines when the brake is released. This pressure is necessary for the system to function effectively, providing the driver with responsive braking.

- Preventing Backflow: When the brakes are applied, air is directed towards the brake chambers. If the air were to flow back into the compressor or other parts of the system when the brakes are released, it could lead to a loss of braking efficiency. The check valve effectively prevents this backflow.

- Enhancing Safety: By ensuring that the air pressure is maintained and preventing contamination from backflow, the check valve contributes significantly to the safety of the vehicle’s braking system. A properly functioning check valve helps to reduce the risk of brake failure.

In summary, the function of the check valve is essential for the safe and effective operation of vehicle air brake systems. Regular inspections and maintenance are necessary to ensure that these components continue to perform as intended.

Importance of Regular Inspection

Regular inspections of the air brake check valve are crucial for ensuring the safety and efficiency of your braking system. The check valve plays a vital role in allowing air to flow in one direction while preventing backflow, which can significantly impact the performance of the brakes. Below are some key reasons why regular inspection should not be overlooked:

- Safety Assurance: One of the primary reasons to regularly inspect the air brake check valve is to ensure the safety of the vehicle and its occupants. A malfunctioning valve can lead to brake failure, which can have catastrophic consequences.

- Optimal Performance: Regular inspections help in maintaining the optimal performance of the braking system. By ensuring that the check valve is functioning correctly, the overall responsiveness of the brakes is enhanced.

- Cost Efficiency: Identifying issues early through regular inspections can save money in the long run. Fixing a small problem before it escalates into a larger issue can prevent costly repairs or replacements.

- Compliance with Regulations: Many jurisdictions have regulations and standards regarding vehicle maintenance. Regular inspections of the air brake check valve help ensure compliance and avoid penalties.

- Increased Longevity: Routine checks can extend the lifespan of your braking components. Preventative maintenance is key to ensuring that the check valve and related parts last longer, providing reliable service.

In summary, the importance of regular inspection of the air brake check valve cannot be overstated. It is essential for maintaining safety, performance, and compliance, while also being a cost-effective strategy for vehicle maintenance.

Signs of a Faulty Check Valve

The check valve plays a critical role in the air brake system of a vehicle, ensuring that air flow is directed appropriately. However, like all components, check valves can experience wear and tear over time, leading to issues that may compromise braking performance. Here are some key signs that indicate a faulty check valve:

- Brake Performance Issues: One of the most noticeable signs of a faulty check valve is a change in brake performance. If the brakes feel spongy or less responsive, it may indicate that the check valve is not functioning properly.

- Air Leaks: Listen for hissing sounds while the brakes are in use. A leaking check valve can introduce unwanted air leaks into the system, resulting in decreased braking efficiency.

- Frequent Activation of the Air Compressor: If the air compressor is cycling more often than usual, it might suggest that the check valve is allowing air to escape, which forces the compressor to work harder to maintain pressure.

- Inconsistent Air Pressure: A malfunctioning check valve can lead to fluctuations in air pressure within the system. If you notice varying pressure readings, it may indicate a problem.

- Visible Damage: Inspect the check valve for any visible signs of damage, such as cracks, corrosion, or broken parts. Physical damage often points to a compromised component.

If any of these signs are observed, it is crucial to conduct a thorough inspection and replace the check valve if necessary. Regular maintenance and vigilance can help prevent ser

Effectiveness of Maintenance Practices

Maintaining an air brake check valve is essential for the safe and efficient operation of air brake systems. Regular maintenance practices can significantly enhance the longevity and reliability of these components. Below are some effective maintenance practices that should be followed:

- Routine Inspections: Conducting regular inspections is crucial. Technicians should check for visible damage, wear and tear, and proper function.

- Cleaning: Keeping the check valve free from dirt and debris is essential. Use appropriate cleaning agents that won’t damage seals or other parts.

- Leak Checks: Performing leak tests can help identify any potential issues. Even a small leak can lead to major failures in an air brake system.

- Replace Worn Parts: If any component of the check valve shows signs of deterioration, it should be replaced immediately to maintain system integrity.

- Lubrication: Appropriate lubrication of moving parts can help in smooth operation and reduce wear.

Regular maintenance not only increases the lifespan of the check valve but also ensures the overall effectiveness of the brake system. It is an investment in safety and efficiency, ultimately leading to reduced operational costs for vehicle fleets.

An ounce of prevention is worth a pound of cure. — Benjamin Franklin

By adhering to these maintenance practices, fleets can mitigate the risks of brake failures and enhance their operational efficiency.

Frequently Asked Questions

What is an air brake check valve?

An air brake check valve is a component in a braking system that prevents backflow of air, ensuring that the brake system retains sufficient pressure to function effectively.

How do air brake check valves work?

Air brake check valves operate by allowing air to flow in one direction while blocking it in the opposite direction, preventing air loss in the braking system.

What are the signs of a faulty air brake check valve?

Signs of a faulty air brake check valve may include leaks, loss of brake pressure, or inconsistent brake performance.

Why is it important to maintain air brake check valves?

Maintaining air brake check valves is crucial for ensuring the safety and reliability of the vehicle’s braking system.

How often should air brake check valves be inspected?

Air brake check valves should ideally be inspected during regular maintenance checks, typically every 10,000 to 15,000 miles, or as recommended by the manufacturer.

Can air brake check valves be repaired, or do they need to be replaced?

In many cases, air brake check valves can be repaired, but if they are severely damaged or corroded, replacement is often recommended.

What impact does a damaged air brake check valve have on vehicle performance?

A damaged air brake check valve can lead to reduced braking efficiency, increased stopping distance, and ultimately, a higher risk of accidents.