Discover the importance, function, and benefits of check valves, along with signs of a faulty valve and its role in brake boosters.When it comes to vehicle safety and performance, every component plays a critical role—and the check valve for the brake booster is no exception. Often overlooked, this small yet vital piece ensures that your braking system operates smoothly and effectively, providing the stopping power you need when it matters most. In this blog post, we will explore what a check valve is and its significance in the broader context of vehicle braking systems. We’ll delve into how a brake booster functions, identify the signs of a faulty check valve, and discuss the benefits of replacing it proactively. Understanding these elements not only enhances vehicle safety but also contributes to improved performance on the road. Let’s dive in!

What is a check valve?

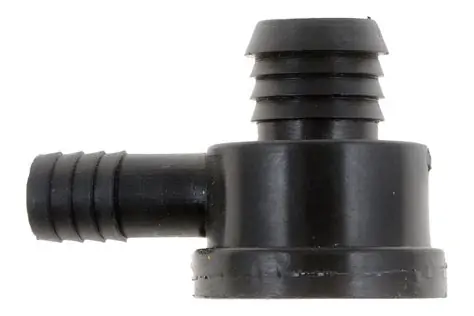

A check valve is a mechanical device designed to allow fluid (liquid or gas) to flow in only one direction. It serves to prevent backflow, ensuring that the flow of essential fluids remains uninterrupted and directed to where it is needed. Often used in various industrial applications, but particularly important in automotive systems, a check valve plays a critical role in maintaining pressure and fluid integrity.

Typically made of materials such as brass, stainless steel, or plastic, check valves come in different designs and configurations. The most common types include:

- Ball Check Valve: Uses a ball that moves to block reverse flow.

- Swing Check Valve: Employs a hinged disc that swings away from the flow path.

- Diaphragm Check Valve: Utilizes a flexible diaphragm to prevent backflow.

In automotive systems, particularly in the brake booster, check valves are essential for ensuring that the brake system functions correctly. They maintain a vacuum pressure, which is crucial for effective braking. The absence or failure of a check valve can lead to serious issues, including an inability to brake properly.

Overall, a check valve is a simple yet vital component in many systems, helping to ensure the proper and efficient functioning of fluid dynamics, and highlighting the importance of choosing the right type for your specific application.

Importance of a check valve

A check valve plays a crucial role in various systems, particularly in hydraulic and pneumatic applications. Its primary function is to allow fluid (liquid or gas) to flow in one direction while preventing backflow, which can cause significant issues in systems such as brake boosters.

Understanding the importance of a check valve is essential for ensuring the proper functioning and reliability of various systems. Below are some key reasons why a check valve is important:

- Prevention of Backflow: The foremost role of a check valve is to prevent backflow, ensuring that fluid moves in the intended direction.

- System Efficiency: By maintaining proper flow direction, check valves contribute to the efficiency and effectiveness of a system, reducing wear and tear on other components.

- Protection of Components: Backflow can cause damage to pumps, motors, and other system parts. A check valve helps protect these components from potential harm.

- Safety: In applications like brake boosters, a malfunctioning valve can lead to loss of braking power and increased risk of accidents. A functioning check valve is essential for safety.

- Maintenance of Pressure: In systems that require a certain pressure level, check valves help maintain and stabilize pressure, ensuring consistent performance.

As you can see, the importance of a check valve cannot be overstated. It is a vital component that supports the functionality, efficiency, and safety of various hydraulic and pneumatic systems, including those involved in automotive braking systems.

Function of a brake booster

A brake booster plays a pivotal role in the *braking system* of a vehicle, enhancing the driver’s ability to slow down or stop. This component utilizes *vacuum pressure* to amplify the force exerted by the driver on the brake pedal, thus improving the overall braking efficiency.

The function of a brake booster can be broken down into several key aspects:

- Enhanced Stopping Power: The brake booster increases the force applied to the brakes, allowing for quicker stops with less effort from the driver.

- Reduced Driver Effort: This component minimizes the physical effort needed to engage the braking system, making it especially beneficial in stop-and-go traffic situations.

- Improved Control: With the additional power provided by the brake booster, drivers can maintain greater control over their vehicle during emergency stops.

- Fuel Efficiency: When a vehicle stops more efficiently, it can contribute to better overall fuel economy.

The brake booster operates by using *atmospheric pressure* and *vacuum* created from the engine to assist in the movement of the brake pedal. When the driver pushes down on the brake pedal, a diaphragm within the booster reacts to the change in pressure, effectively multiplying the force. This action ensures that the brakes apply smoothly and effectively, enhancing safety for both the driver and passengers.

In summary, the function of a brake booster is crucial for safe and efficient vehicle operation, making it an essential component of any modern braking system.

Signs of a faulty check valve

Understanding the signs of a faulty check valve is crucial for maintaining an efficient braking system in your vehicle. A properly functioning check valve in a brake booster ensures that your brake system operates smoothly. When this component starts to fail, it can lead to a variety of issues that may compromise your vehicle’s safety.

Here are some common indicators of a malfunctioning check valve:

- Hard Brake Pedal: One of the most noticeable signs of a faulty check valve is a hard brake pedal. If you find that you have to exert more pressure to engage the brakes, it could indicate a problem with the check valve.

- Reduced Brake Assist: A proper check valve allows the brake booster to assist in braking. If you experience a noticeable decrease in this assistance, it might be due to a failing check valve.

- Braking Delays: If there is a delay in braking response time, this could be a symptom of a malfunction. The check valve should help provide immediate brake pressure when needed.

- Hissing Noise: A hissing or vacuum leak sound when pressing the brake pedal can indicate that the check valve is not sealing correctly. This sound is often accompanied by diminished braking performance.

- Dashboard Warning Lights: Some vehicles are equipped with warning lights that can illuminate if there is a problem within the braking system, including issues related to the check valve. Always pay attention to these warnings.

If you notice any of these symptoms, it is essential to have your vehicle inspected by a qualified technician. Addressing the issue promptly can prevent further complications and ensure your safety on the road.

In summary, being aware of the signs of a faulty check valve can save you from potential hazards and costly repairs. Regular maintenance and monitoring of your vehicle’s braking system are key to a safe driving experience.

Benefits of replacing the check valve

Replacing the check valve in your vehicle, particularly in the context of a brake booster, is essential for maintaining optimal performance and safety. Here are some key benefits of replacing this crucial component:

- Enhanced Brake Performance: A functioning check valve ensures that the brake booster operates efficiently, providing adequate force to the braking system, which results in improved stopping power.

- Increased Safety: A faulty check valve can hinder the proper vacuum supply to the brake booster, leading to longer stopping distances and potential brake failure. Replacing it can significantly enhance vehicle safety.

- Prevention of Further Damage: Ignoring a malfunctioning check valve can result in more extensive damage to the brake booster and the entire braking system. Replacement can save you from costly repairs in the long run.

- Improved Vacuum Efficiency: A new check valve ensures that the engine maintains the necessary vacuum levels, which is crucial for the proper functioning of the brake booster. This not only improves brake response but also supports the overall efficiency of the vehicle.

- Reduced Maintenance Costs: Regularly replacing the check valve can minimize the risk of breakdowns and costly emergency repairs, helping you save money over time.

In summary, replacing the check valve is a small yet impactful maintenance task that leads to better brake performance, enhanced safety, and fewer long-term repair costs. Always consult with a certified mechanic to ensure proper installation and functionality.

Frequently Asked Questions

What is a check valve and how does it function in a brake booster?

A check valve is a device that allows fluid to flow in one direction while preventing backflow. In a brake booster, it ensures that the vacuum pressure created when the engine operates is maintained, allowing for effective brake application.

Why is a check valve important for brake boosters?

The check valve is crucial for brake boosters because it helps maintain consistent vacuum pressure, which is essential for providing the necessary boost in braking power. Without it, the brake system may lose efficiency, leading to increased stopping distances.

What are common signs of a faulty check valve in a brake booster?

Common signs of a faulty check valve include a hissing sound when the brakes are applied, a hard brake pedal, and reduced braking effectiveness. These symptoms indicate that vacuum pressure is not being properly maintained.

How can you test whether a check valve is working properly in a brake booster?

To test a check valve, you can remove it from the system and use a handheld vacuum pump to check its operation. The valve should allow airflow in one direction but block it when reversed. If it leaks in either direction, it is likely faulty.

How often should a check valve in a brake booster be inspected or replaced?

It’s recommended to inspect the check valve during regular vehicle maintenance, but replacement may be necessary every 50,000 to 100,000 miles, or if symptoms of failure arise.

Can a check valve failure affect other components in the braking system?

Yes, a check valve failure can lead to brake system inefficiencies, potentially causing excessive wear on brake components, increased brake pedal effort, and even complete brake failure in severe cases.

What should a vehicle owner do if they suspect a problem with their check valve?

If a vehicle owner suspects a problem with their check valve, they should have their brake system inspected by a qualified mechanic. Prompt attention to issues can prevent more severe damage to the braking system.