Learn about spring brakes, their automatic activation, inspection procedures, testing methods, and common issues to ensure optimal performance and safety in your vehicle.When it comes to vehicle safety, understanding the functionality of spring brakes is crucial, especially for heavy-duty trucks and commercial vehicles. Designed to engage automatically in the event of a braking failure, these systems are vital for preventing accidents and ensuring the driver’s safety. In this blog post, we’ll explore how you can check if the spring brakes come on automatically, delving into the mechanics behind spring brakes, the importance of their automatic activation, and the inspection and maintenance procedures involved. We’ll also discuss how to effectively test the spring brake system and address common issues that may arise. Whether you’re a seasoned mechanic or a vehicle owner wanting to ensure your vehicle’s reliability, this guide will equip you with the knowledge you need for safe travels.

Understanding Spring Brakes

Spring brakes are a crucial component in the braking systems of heavy-duty vehicles, ensuring safety and reliability during operation. They primarily serve to provide a fail-safe mechanism that activates automatically in the event of air loss in the brake system. In this section, we will delve into the workings of spring brakes, their importance, and how to check their automatic activation.

What are Spring Brakes?

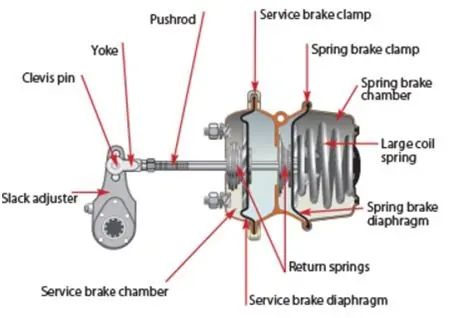

Spring brakes consist of a spring mechanism that is used in conjunction with the service brake system. When the vehicle’s air supply is intact, the spring brakes remain in a released state, allowing for normal braking functionality. However, if there is a loss of air pressure, these brakes engage automatically to stop the vehicle.

Importance of Automatic Activation

The automatic activation of spring brakes is vital for maintaining vehicle safety. In situations where hydraulic systems fail or air pressure drops unexpectedly, the spring brakes will engage to prevent uncontrolled movement. This characteristic makes them particularly important for:

- Trucks and Trailers – Prevents rollaway incidents.

- Commercial Vehicles – Provides an added layer of safety when transporting goods.

- Heavy Equipment – Ensures stability during loading and unloading operations.

How to Check Automatic Activation

It is essential to regularly check the functionality of the spring brakes to ensure they will activate automatically when needed. Below are some recommended inspection steps:

- Visual Inspection – Check the spring brake assemblies for any signs of wear or damage.

- Air Pressure Test – Ensure that the system maintains the proper air pressure levels. A drop below the manufacturer’s specifications can indicate a problem.

- Activate Emergency Brake – Manually activate the emergency brake to see if the spring brakes engage correctly.

- Listen for Air Leaks – Examine the system for air leaks by listening carefully when the brakes engage. Any hissing sound could indicate a malfunction.

- Professional Inspection – Have a certified mechanic evaluate the braking system periodically for optimal performance.

Conclusion

A deep understanding of spring brakes and their automatic activation is crucial for all vehicle operators, especially in the heavy-duty sector. Regular inspections and maintenance procedures will ensure that these brakes function effectively, enhancing the safety of both the driver and other road users.

Importance of Automatic Activation

The automatic activation of spring brakes is crucial for ensuring the safety and reliability of heavy vehicles. When the primary braking system fails, the spring brake system serves as a backup, automatically engaging to bring the vehicle to a safe stop. Let’s explore why this feature is so significant.

Key Benefits of Automatic Activation

- Enhanced Safety: Automatic spring brakes significantly reduce the risk of accidents due to brake failure.

- Reliability: With the automatic activation feature, drivers can trust that the spring brakes will engage when needed most.

- Minimized Downtime: Automatic activation helps in keeping the vehicle operational by preventing catastrophic brake system failures.

- Compliance with Regulations: Many jurisdictions mandate that vehicles must have reliable emergency braking systems, making automatic activation essential for legal compliance.

How it Works

The system relies on a specific pressure threshold. If the air pressure drops below a certain level (often due to a leak or malfunction), tension in the springs forces the brake shoes against the brake drum, effectively stopping the vehicle.

Automatic activation is not just a feature; it’s a critical safety measure that saves lives on the road.

Importance in Different Scenarios

| Scenario | Significance of Automatic Activation |

|---|---|

| Emergency Stops | Ensures quick and reliable stopping action, preventing collisions. |

| Long Downgrades | Prevents runaway vehicles by automatically engaging when necessary. |

| Brake System Failures | Acts as a fail-safe to protect the driver and other road users. |

In summary, the automatic activation of spring brakes plays an invaluable role in vehicle safety and performance. Regular inspections and maintenance of this system are crucial to ensure its proper functioning, thereby safeguarding both the driver and the public.

Inspection and Maintenance Procedures

Inspecting and maintaining spring brakes is crucial for ensuring the safety and reliability of heavy vehicles. Regular checks and timely maintenance can prevent issues that may compromise the braking system’s performance. Below are key procedures to follow:

1. Visual Inspection

- Check for leaks in the air lines and between the spring brake chamber and the actuator.

- Inspect the condition of the spring brake assembly for any signs of wear or damage.

- Examine the mounting brackets and bolts for tightness and corrosion.

2. Functional Testing

Perform a series of tests to ensure the automatic activation of the spring brakes:

- Engage the parking brake to ensure it activates the spring brakes.

- Release the parking brake and validate that the brakes release properly.

- Test the system under load to check for consistent engagement and release.

3. Air System Checks

Regularly inspect the air supply system for:

- Air pressure: Ensure it meets system specifications.

- Soundness: Verify that the air tanks are free of moisture and contaminants.

- Functionality: Listen for any unusual noises during brake operation that could indicate a problem.

4. Lubrication

Ensure that all moving parts of the spring brake system are adequately lubricated. This helps minimize wear and tear and prevents corrosion:

- Use appropriate lubricants as specified in the manufacturer’s guidelines.

- Apply grease to pivot points and other moving parts regularly.

5. Professional Inspections

Consider having a certified technician conduct a thorough inspection of the spring brake system at regular intervals. This should include:

- Comprehensive diagnostics of electronic control systems.

- Replacement of any components that show excessive wear.

- Calibrating and adjusting the system to manufacturer specifications.

By adhering to these inspection and maintenance procedures, vehicle operators can ensure that their spring brakes function optimally, thereby enhancing safety and performance.

Testing the Spring Brake System

The spring brake system is a crucial component in heavy vehicles, ensuring safety by providing a reliable means of braking when air pressure drops. Regularly testing this system helps maintain its functionality and ensures the safety of drivers and vehicles on the road. Here’s how to effectively test the spring brake system.

1. Preparation for Testing

- Ensure the vehicle is in a safe area where you can perform the test without any hazards.

- Check that the vehicle’s air system is properly charged to the recommended pressure.

- Have a pressure gauge on hand to monitor the air pressure levels.

2. Testing Procedure

- Visual Inspection: Start by conducting a visual inspection of the spring brake assemblies for any visible signs of damage, such as cracks or leaks.

- Air Pressure Check: Verify that the air pressure is within acceptable limits, typically between 90 and 120 psi.

- Engage the Spring Brakes: Manually engage the spring brakes by turning off the ignition and allowing the air pressure to drop. The brakes should engage automatically when the pressure falls below a certain threshold (usually around 40-60 psi).

- Release the Brakes: Restart the engine and build air pressure back up to the normal operating range. Verify that the spring brakes release as the pressure increases.

3. Additional Checks

For a more thorough testing of the spring brake system, consider the following:

- Test the manual control for the spring brakes to ensure it functions properly.

- Ensure that the air supply system and valves are free from contamination and functioning correctly.

- Inspect the brake chambers for any signs of wear or tears in the diaphragm.

4. Troubleshooting Common Issues

If the spring brakes do not engage or release as expected, common issues may include:

- Low Air Pressure: Insufficient air pressure might be preventing engagement. Check for leaks in the air system.

- Faulty Valves: Ensure all valves in the air brake system are working to supply air effectively.

- Defective Spring Brake Chamber: If the chamber is damaged, it may need replacement to ensure proper function.

5. Final Recommendations

After testing, always document the results, and if any problems are noticed, it’s essential to address them immediately to ensure the safety and reliability of the braking system. Regular inspections and maintenance are key to keeping the spring brake system in optimal working condition.

Remember, safety is paramount, and understanding how to test your spring brake system is a vital part of vehicle maintenance.

Addressing Common Issues

When dealing with spring brakes, it is crucial to be vigilant about identifying and addressing common issues that may arise. Proper maintenance and understanding of potential problems can greatly enhance the performance and safety of your braking system.

Common Issues with Spring Brakes

- Brake Not Engaging: One of the most common issues is the spring brake not engaging when the vehicle is in a parked position. This could be due to a malfunctioning control valve or a loss of air pressure.

- Air Leaks: Air leaks in the system can lead to pressure loss, causing the brakes to fail. Inspecting hoses, fittings, and seals regularly can help identify leaks early.

- Excessive Wear: Over time, brake components can wear down. Regular inspection of brake linings and other essential parts is key to ensuring longevity.

- Corrosion and Rust: Exposure to moisture can cause parts of the spring brake system to corrode. Keeping components clean and applying protective coatings can help mitigate this issue.

- Faulty Dash Warning Light: If the dash warning light for the spring brake system is malfunctioning, it may not alert the driver when there’s an issue. Regularly check the dashboard indicators and replace any defective lights.

How to Address These Issues

Addressing these common issues effectively requires a combination of regular inspection and proactive maintenance procedures. Here are some recommendations:

- Maintain Air Pressure: Regularly check for appropriate air pressure levels in the braking system, ensuring all components are functioning correctly.

- Conduct Routine Checks: Schedule regular inspections to assess the condition of the brake lining, hoses, and other critical parts.

- Repair or Replace Faulty Components: Immediately replace any damaged or worn-out components to prevent further issues.

- Document Maintenance Procedures: Keeping detailed records of inspections and repairs can help track the health of the spring brake system over time.

- Consult a Professional: If unsure about any aspect of the spring brake system, seeking the expertise of a qualified technician is advisable.

By being aware of these common issues and taking the necessary precautions, vehicle operators can ensure the effective performance of spring brakes, thus enhancing safety on the road.

Frequently Asked Questions

What are spring brakes and how do they work?

Spring brakes are a type of braking system used in large vehicles, such as trucks and buses. They use a spring mechanism to apply brakes in case of air pressure loss, ensuring the vehicle remains stationary.

Why is it important for spring brakes to engage automatically?

It is crucial for spring brakes to engage automatically to prevent accidents or rollaways when air pressure in the braking system drops, ensuring the vehicle remains safe and under control.

How can I check if the spring brakes are working correctly?

To check if your spring brakes are working properly, conduct a pre-trip inspection that includes testing the air pressure gauge, performing a leak test, and checking the functionality of the spring brake push rod.

What tools are needed to check the spring brakes?

You may need a pressure gauge, a flashlight for visual inspections, and potentially a brake tester to assess the functionality of the spring brakes effectively.

What signs indicate that spring brakes may not be functioning properly?

Signs of malfunction can include abnormal noises when the brakes are engaged, leaks in the air lines, or the brakes not releasing as expected when air pressure is applied.

Is it safe to drive a vehicle if the spring brakes are not engaging automatically?

No, it is not safe to drive a vehicle with faulty spring brakes. It is critical to address any issues before operating the vehicle to avoid potential accidents.

Where can I find professional help if I suspect issues with my spring brakes?

You can consult a certified mechanic or an automotive service center that specializes in heavy vehicles. They have the expertise and tools necessary to conduct thorough inspections and repairs.